Digital

Jet-Press-720S next generation B2 inkjet press

The future of commercial inkjet printing: Fujifilm’s powerful second generation B2 sheet-fed digital inkjet press

Fuji Jet-Press-720S

Fuji Jet-Press-720S

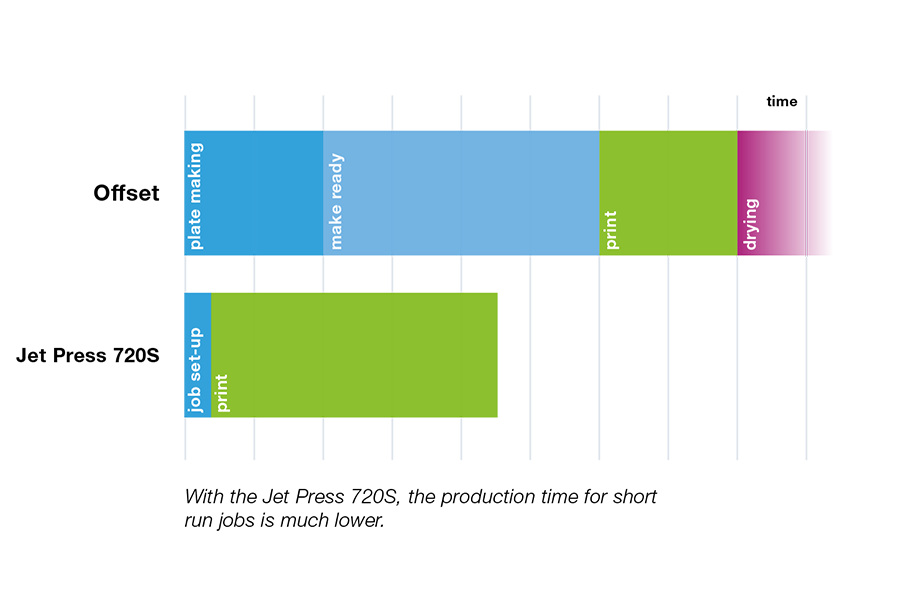

Produce efficient short run print

The most efficient way to produce short run print is to send the PDF to the press and print. This is how the Jet Press 720S operates; a groundbreaking B2 inkjet press that eliminates all the timely and costly preparation and set up parameters of an offset press. There are no plates to produce, no platesetters or processors to maintain, no make readies, no run up to colour, no waste sheets, and virtually no pressroom consumables. The printed sheets can often be handled immediately, with print quality and consistency guaranteed, and no on-press tweaks necessary. So, if you want to be ultra-competitive on short run print jobs, the Jet Press 720S is about as efficient as you can get. Just send the PDF and print.

Outstanding image quality

The Jet Press 720S takes the print quality produced by a digital printing system to new heights. The end result is stunning, vibrant colours, superb skin tones, extraordinary fine text and line detail,and incredible flat tints, all produced on standard offset paper. However, the perception of print quality is not only limited to the technical specifications. There is a tactile, emotional and physical element to a piece of high quality print that sets it apart. For the first time, the Jet Press 720S allows these intangible qualities to be reproduced digitally, setting it apart from the rest. Truly the dawn of a new era for digital print.

Double-sided variable data handling

The ability to handle variable data is a fundamental advantage of a digital press, and the Jet Press 720S is no different even though it is a single sided press. This is because it takes advantage of a system that prints a barcode in the non-image area of every sheet immediately after the paper leaves the input sheet stacker. Once the first side has been printed, the sheets are turned over and loaded once again. The press reads the barcode on every sheet as it leaves the stacker and downloads the correct page information before it prints the second side (in 3.3 seconds to be exact), guaranteeing front and back page matching. The introduction of new ultra-high capacity servers and data transfer system mean the Jet Press 720S is able to print the second side on-the-fly at the full press speed of 2700 B2 sheets per hour.